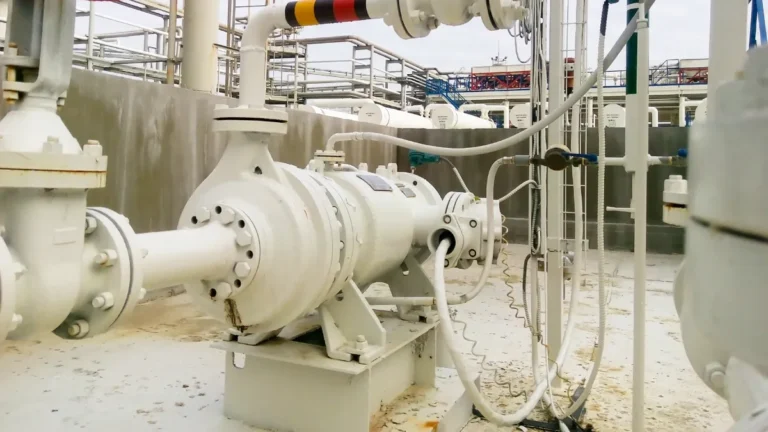

An abrasive slurry pump is a specialized pump designed to handle tough mixtures of liquids and solid particles, commonly used in industries such as mining, dredging, power generation, and wastewater treatment. Unlike standard pumps, which quickly wear out when exposed to abrasive materials, these pumps are engineered with heavy-duty construction, wear-resistant materials, and advanced hydraulic designs to ensure durability and consistent performance. With the growing demand for reliable slurry pumping solutions, leading slurry pump manufacturers are focusing on innovative designs that reduce downtime, extend service life, and optimize energy efficiency. This article explores what makes an abrasive slurry pump unique and highlights the key design features that make it indispensable in harsh operating environments.

Defining the Abrasive Slurry Pump Beyond Basics

An abrasive slurry pump is a specialized type of pump engineered to move mixtures of liquid and solid particles, often found in industries such as mining, dredging, power generation, and mineral processing. Unlike standard pumps, which are designed for clear or lightly contaminated fluids, abrasive slurry pumps are built to withstand the high levels of wear caused by coarse, dense, or sharp solid particles suspended in liquid. The design emphasizes heavy-duty construction, wear-resistant materials, and optimized flow paths to ensure long-term reliability and efficiency in harsh operating environments.

What Sets an Abrasive Slurry Pump Apart from Standard Pumps

Abrasive slurry pumps feature unique components and engineering solutions tailored to handle the challenging conditions of slurry pumping. Key differences include:

- Reinforced casing and impellers designed to resist wear from abrasive particles.

- Replaceable liners made from high-chrome alloys, rubber, or other abrasion-resistant materials.

- Specialized sealing systems that minimize leakage and prevent contamination of pump bearings.

- Lower operating speeds compared to standard pumps, which reduce internal friction and extend the life of parts.

While standard pumps are designed to move fluids efficiently, they often lack the structural strength and protective features necessary to handle abrasive, high-density slurries.

Differences Between Abrasive and Non-Abrasive Slurries

Non-abrasive slurries contain fine or soft particles that cause minimal wear on pump components. In contrast, abrasive slurries often contain hard materials, such as sand, gravel, crushed rock, or mineral ores, that can rapidly erode metal or elastomer surfaces within the pump. This selection of pump material and design is critical when dealing with abrasive slurries, a challenge that slurry pump manufacturers address through advanced material technology and custom engineering.

Why Conventional Pumps Fail in Slurry Pumping

Conventional pumps are not built to tolerate the continuous impact and friction caused by solid particles in abrasive slurries. The thin walls, standard impellers, and lack of wear protection lead to:

- Premature wear and tear, resulting in frequent breakdowns.

- Loss of hydraulic efficiency due to erosion of critical parts.

- High maintenance costs and reduced uptime in demanding operations.

For these reasons, industries relying on slurry pumping depend on robust, purpose-built abrasive slurry pumps designed by specialized slurry pump manufacturers to ensure consistent performance and durability.

The Mechanics of Moving Abrasive Slurries

An abrasive slurry pump is engineered to transport a mixture of liquid and solid particles while minimizing wear and maintaining efficient performance. The mechanics of slurry movement depend heavily on the design of the pump’s components, the flow dynamics within the casing, and the materials used to withstand the abrasive nature of the slurry. Leading slurry pump manufacturers focus on these factors to deliver pumps that can handle demanding slurry pumping applications.

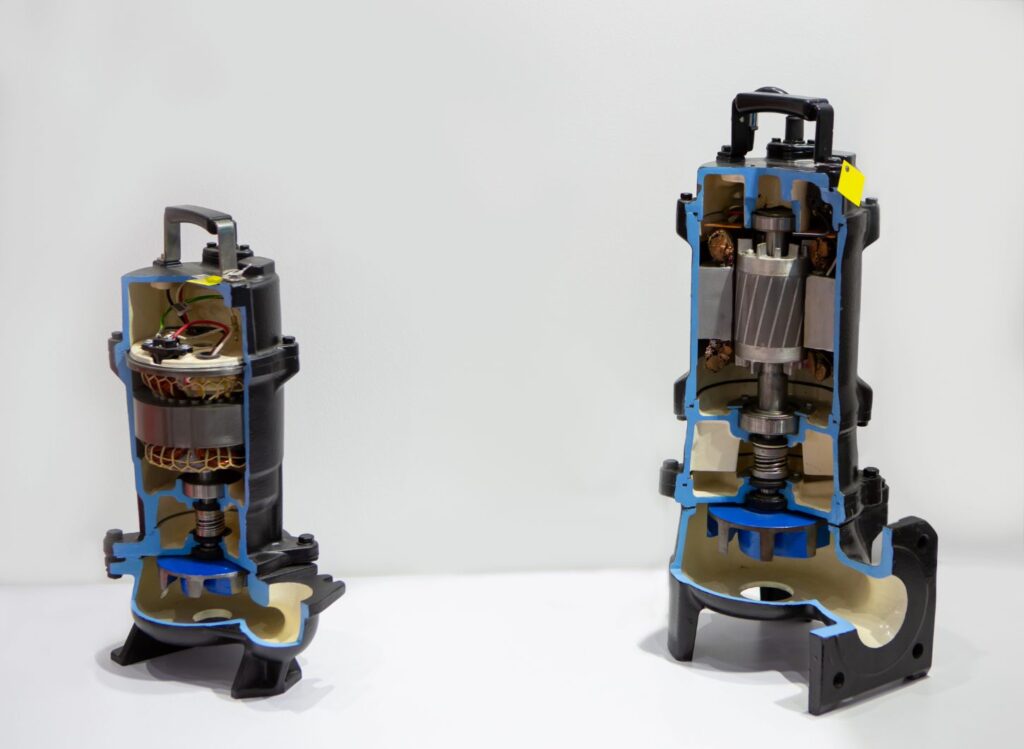

Key Components of an Abrasive Slurry Pump

The internal parts of a slurry pump are specifically designed to endure the harsh impact and erosion caused by abrasive particles:

- Impeller: The rotating component responsible for transferring energy to the slurry. Abrasive slurry pump impellers are often made of high-chrome alloys or coated with elastomer to resist wear.

- Casing: Encases the impeller and directs the flow of slurry. The casing is typically reinforced with wear-resistant liners to extend operational life.

- Shaft and Bearings: The shaft transmits power from the motor to the impeller, while heavy-duty bearings ensure smooth rotation under high load conditions.

- Liners: These replaceable components protect the pump casing from direct contact with abrasive slurries, reducing maintenance costs and downtime.

Pump Flow Dynamics and Abrasive Handling

The flow dynamics within an abrasive slurry pump are carefully designed to reduce particle collisions and turbulence, which are primary causes of wear. Features such as optimized volute shapes, large internal clearances, and streamlined flow paths ensure that particles are transported efficiently while minimizing damage to the pump’s internal surfaces. This design philosophy enables consistent slurry pumping performance even in high-solid-content applications.

Importance of Speed and Materials in Pump Performance

Operating speed directly influences the wear rate of pump components. Lower speeds are preferred in abrasive slurry pumps, as they reduce frictional forces and extend the service life of the impeller and liners. Additionally, material selection plays a critical role. High-chrome steel, natural rubber, and advanced ceramics are common choices by slurry pump manufacturers due to their superior abrasion resistance. Using the right combination of speed control and durable materials ensures optimal efficiency and reduced downtime in abrasive applications.

Why Slurry Pumping Is Tough on Equipment

Handling abrasive slurries presents unique challenges that place significant stress on pumping equipment. Unlike clear water or non-abrasive fluids, slurries contain solid particles that continuously impact and erode internal components. Even the most advanced abrasive slurry pump designs from leading slurry pump manufacturers must account for these harsh conditions to ensure reliable performance and longevity.

Common Wear and Tear Challenges

The primary issue in slurry pumping is the accelerated wear caused by hard and coarse particles such as sand, gravel, or mineral ores. These particles strike the impeller, casing, and liners, gradually wearing down their surfaces. Key problems include:

- Erosion: The continuous impact of solid particles results in material loss on impellers and casings.

- Corrosion: Certain slurries, especially those containing chemicals, can corrode pump surfaces, further weakening components.

- Seal and bearing damage: Abrasive particles can infiltrate seals and bearings, causing leakage or mechanical failure.

Heat, Cavitation, and Efficiency Issues

Improper flow dynamics or insufficient lubrication can generate heat within an abrasive slurry pump, accelerating material fatigue. Cavitation—caused by vapor bubbles forming and collapsing in the slurry—can erode metal surfaces rapidly. These conditions not only reduce pump efficiency but also increase energy consumption and maintenance costs.

Limitations Faced by Even Top Slurry Pump Manufacturers

While advanced materials, such as high-chrome alloys and rubber linings, improve durability, no pump is completely immune to abrasive wear. Even the best slurry pump manufacturers face the challenge of balancing cost, weight, and efficiency with durability. Over time, all components require inspection, maintenance, or replacement due to the demanding nature of slurry pumping operations.

Design Elements That Define Durability

The ability of an abrasive slurry pump to operate in harsh conditions is determined by its structural design and the materials used in its construction. Unlike standard pumps, which are not built for constant exposure to abrasive particles, slurry pumps incorporate heavy-duty features and engineered components that extend operational life and reduce maintenance frequency. Leading slurry pump manufacturers focus on design innovations to meet the rigorous demands of slurry pumping across various industries, including mining, dredging, and power generation.

Heavy-Duty Build and Reinforced Components

An abrasive slurry pump is engineered with a thicker casing, robust frames, and heavy-duty shafts to handle the impact and stress of transporting solid-laden fluids. These reinforcements ensure the pump can withstand high pressures and abrasive environments without deforming or losing performance efficiency. Additional structural supports are often incorporated to minimize vibration and improve overall stability during operation.

Wear-Resistant Materials Like High-Chrome Alloys

Material selection is a critical factor in pump longevity. High-chrome alloys, natural rubber, polyurethane, and advanced ceramics are commonly used in components like impellers, liners, and casings. These materials offer exceptional resistance to erosion and corrosion, which is essential for maintaining consistent performance in slurry pumping applications. By utilizing these advanced materials, slurry pump manufacturers reduce the frequency of part replacements and downtime.

Impeller Designs Suited for Abrasives

Impellers are designed with large, open passages that allow solid particles to pass through without clogging or blocking. In abrasive applications, open or semi-open impellers are often preferred to minimize wear from particle impacts. The impeller design also optimizes flow patterns, reducing turbulence and ensuring that the abrasive slurry pump operates at maximum hydraulic efficiency.

Advanced Seal Systems and Adjustable Clearances

Seal integrity is crucial for preventing leaks and protecting internal components from abrasive particles. Mechanical seals, expeller seals, and gland packing systems are commonly used in slurry pumps to provide reliable sealing under harsh conditions. Adjustable clearances between the impeller and wear plate enable operators to fine-tune the pump for optimal efficiency, compensating for wear over time —a key design feature offered by top slurry pump manufacturers.

Materials That Outlast Abrasive Environments

The selection of materials is a critical factor in ensuring the longevity and efficiency of an abrasive slurry pump. The constant exposure to hard, sharp, and corrosive particles requires materials that can withstand severe wear and maintain performance over extended periods. Leading slurry pump manufacturers utilize a combination of advanced metals, elastomers, and ceramics to construct pumps that can withstand the most demanding slurry pumping environments.

High-Chrome Iron, Elastomers, and Ceramics

High-chrome iron, with its excellent hardness and abrasion resistance, is commonly used for impellers, liners, and other high-wear areas of an abrasive slurry pump. For certain applications, elastomers such as natural rubber or polyurethane are preferred, as they offer flexibility and superior resistance to cutting or tearing caused by sharp particles. Advanced ceramics are also used in specific components where extreme hardness and erosion resistance are required, making them ideal for handling slurries with highly abrasive or corrosive properties.

Matching Pump Materials to Slurry Properties

Not all slurries are the same, and the composition of the slurry—particle size, shape, density, and chemical makeup—determines the most suitable material. For example, high-chrome alloys perform well with coarse, heavy particles, while elastomers are more effective for fine particles or slurries containing corrosive chemicals. The correct material combination reduces wear rates, ensuring the abrasive slurry pump operates efficiently with minimal downtime.

How Slurry Pump Manufacturers Select Optimal Materials

Experienced slurry pump manufacturers evaluate the characteristics and operating conditions of slurry, including temperature, pH levels, and solid content, before recommending suitable material configurations. This careful selection process ensures that each pump is tailored to withstand the specific challenges of its intended application. The use of hybrid material designs—combining metals with elastomers or ceramics—further enhances durability and extends the life of critical components in slurry pumping operations.

Where Abrasive Slurry Pumps Excel

An abrasive slurry pump is indispensable in industries where the movement of solid-laden fluids is a daily requirement. Its robust design, advanced materials, and heavy-duty construction make it ideal for handling high-density, abrasive, and corrosive slurries that would quickly damage standard pumping equipment. Slurry pump manufacturers develop specialized solutions to meet the unique needs of industries such as mining, dredging, power generation, and wastewater treatment, where reliability and durability are critical.

Mining and Mineral Processing

In mining operations, abrasive slurry pumps are used to transport tailings, ore concentrates, and other mineral-rich slurries. These slurries often contain sharp and dense particles that can erode conventional pumps within days. By using wear-resistant materials and optimized impeller designs, slurry pumping systems in mining ensure consistent material flow and reduced downtime, even in the most demanding conditions.

Dredging and Marine Applications

Dredging operations involve moving sand, gravel, and sediment from riverbeds, harbors, or seabeds. An abrasive slurry pump is essential for efficiently handling these abrasive materials. Its ability to manage large solid particles without clogging or excessive wear makes it the preferred choice for dredging contractors and marine construction projects.

Power Generation and Ash Handling

Coal-fired power plants generate ash and other byproducts that must be transported as slurry for disposal or processing. Abrasive slurry pumps are widely used in these plants for ash and fly ash handling systems. Their durability reduces maintenance intervals, ensuring smooth and cost-effective slurry pumping in high-volume applications.

Wastewater and Industrial Processing

In wastewater treatment plants and industrial facilities, abrasive slurries such as sludge or chemical residues require reliable pumping solutions. Pumps designed by top slurry pump manufacturers are equipped to handle these corrosive and abrasive fluids while maintaining energy efficiency and reducing operational costs.

Benefits of Slurry Pumping in These Sectors

- Extended equipment life due to wear-resistant designs.

- Reduced maintenance and downtime, increasing operational productivity.

- Improved material handling efficiency for large and abrasive solids.

- Custom-engineered solutions by leading slurry pump manufacturers for specific industry requirements.

Keeping Pumps Battle-Ready

Maintaining an abrasive slurry pump is critical for ensuring consistent performance and reducing unplanned downtime. The constant exposure to abrasive particles, corrosive fluids, and high-pressure operations accelerates wear on internal components, making preventive maintenance and timely replacement of parts essential. By adopting proactive strategies and collaborating with reputable slurry pump manufacturers, operators can prolong the lifespan of their pumps and optimize efficiency in slurry pumping operations.

Preventive Maintenance Practices

Routine maintenance plays a key role in preserving pump performance. This includes:

- Regular inspections of impellers, liners, and seals for signs of wear or damage.

- Monitoring pump performance metrics such as flow rate, pressure, and vibration to detect early signs of inefficiency.

- Lubricating bearings and rotating components to prevent friction-related damage.

- Cleaning and flushing the pump housing to remove debris that can cause abrasion or clog the pump.

Part Replacement Strategies and Inspection Intervals

Replacing worn parts before they fail is crucial to avoid costly breakdowns. Components like impellers, liners, and mechanical seals are designed to be replaceable in an abrasive slurry pump. Establishing a maintenance schedule based on operating conditions, slurry composition, and usage hours ensures optimal performance. For high-wear environments, inspections may be required on a weekly or monthly basis, while less demanding applications can have longer intervals.

Partnering with Slurry Pump Manufacturers for Upkeep

Working with experienced slurry pump manufacturers offers significant advantages in maintaining and upgrading equipment. Manufacturers provide OEM parts, maintenance kits, and technical support specifically tailored to each model and application. Many also offer training programs to ensure operators follow best practices in slurry pumping maintenance, minimizing the risk of downtime and extending equipment life.

Selecting a Pump That Won’t Quit

Choosing the right abrasive slurry pump is crucial for achieving reliable performance, minimizing downtime, and reducing operational costs. Every slurry application is unique, and the wrong pump design or material selection can lead to premature wear, energy inefficiencies, and increased maintenance requirements. By focusing on key parameters and collaborating with experienced slurry pump manufacturers, operators can ensure that their slurry pumping system is optimized for both efficiency and longevity.

Key Parameters: Particle Size, Flow Rate, and Density

The type of slurry being pumped directly influences the choice of pump configuration:

- Particle Size: Larger, coarse particles require open or semi-open impeller designs to prevent clogging and minimize wear. Fine particles, on the other hand, may benefit from elastomer-lined components.

- Flow Rate and Head Requirements: The pump must be sized to handle the required volume of slurry at the necessary pressure without overloading the motor or sacrificing efficiency.

- Slurry Density: High-density slurries with a large percentage of solids demand a pump with robust construction, lower operating speeds, and high-torque capabilities to ensure consistent performance.

Custom Solutions from Slurry Pump Manufacturers

Leading slurry pump manufacturers design and configure pumps based on specific application requirements. They consider factors like temperature, chemical composition, and abrasive properties of the slurry when recommending materials, impeller types, and sealing solutions. Custom-engineered pumps ensure that the system can handle extreme conditions while maintaining maximum efficiency.

Balancing Efficiency and Longevity in Slurry Pumping

An effective abrasive slurry pump should not only move materials efficiently but also minimize wear and energy consumption. Adjusting pump speed, selecting the right liner materials, and optimizing the hydraulic design are all crucial steps in striking a balance between operational efficiency and long-term durability. Partnering with experienced manufacturers helps operators strike the right balance, reducing total ownership costs over time.

Driving Performance in Harsh Environments

An abrasive slurry pump is more than just heavy-duty equipment—it is the backbone of efficient slurry pumping operations in demanding industries like mining, dredging, and wastewater management. With the right design, materials, and maintenance strategies, these pumps deliver long-lasting performance and reduced downtime. Partnering with expert slurry pump manufacturers ensures access to tailored solutions that match the specific needs of challenging applications. If your project requires reliable slurry handling or dredging support, Virginia Dredging offers the expertise and equipment to keep your operations running smoothly. Contact us today to discuss your requirements and discover the ideal solution for your most demanding pumping challenges.