Slurry pumps are essential for efficiently handling abrasive, high-viscosity materials across various industries, including mining, construction, and wastewater treatment. These pumps are designed to withstand the harsh demands of transporting slurry, a mixture of solids and liquids, over long distances and in challenging conditions. Selecting the right slurry pump supplier and ensuring the proper maintenance of key components is crucial for maximizing operational efficiency, reducing downtime, and extending the lifespan of your equipment. In this article, we examine the crucial role of slurry pump suppliers, the significance of high-quality pump parts, and how to select a manufacturer that will meet your project requirements.

What Are Slurry Pumps?

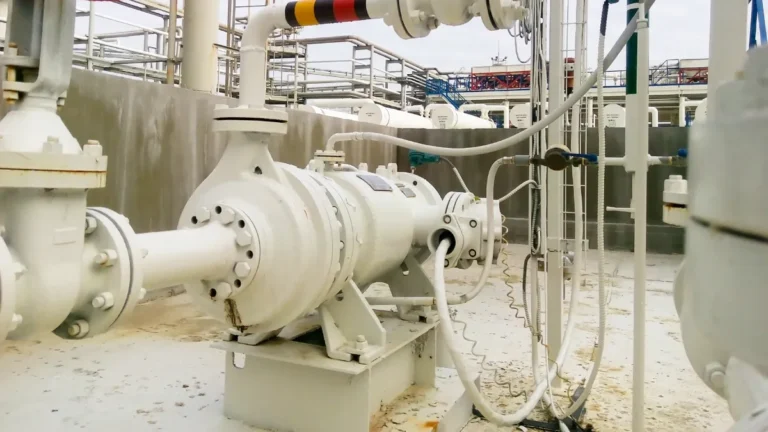

Slurry pumps are specialized industrial pumps designed to handle mixtures of liquids and solid particles, often referred to as slurry. These pumps are critical in industries such as mining, construction, wastewater treatment, and dredging, where transporting abrasive and high-viscosity fluids is required. Unlike conventional pumps, which primarily transport clean water or other low-viscosity fluids, slurry pumps are designed to withstand the added wear and tear caused by solid particles in the slurry, ensuring efficient and reliable performance in harsh conditions.

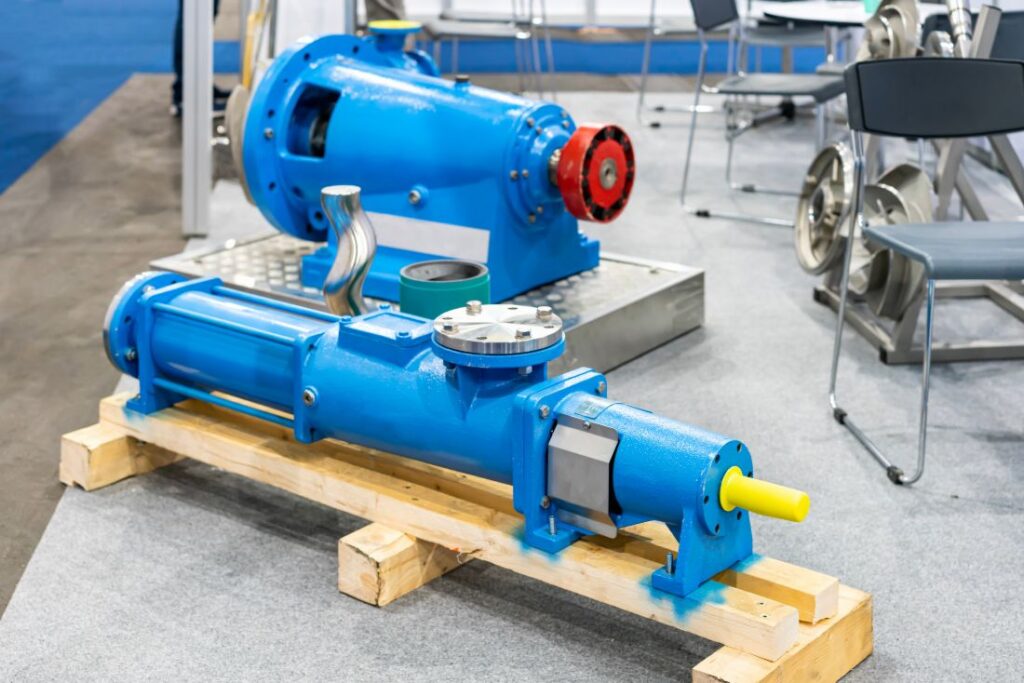

Key Components of a Slurry Pump

The core components of a slurry pump include:

- Casing: The casing is the outer shell of the slurry pump, designed to contain the slurry as it moves through the pump. The casing is typically made of durable, corrosion-resistant materials to withstand the abrasive nature of the slurry. Many slurry pump suppliers offer casings made from high-chrome alloys or rubber-lined materials for enhanced durability.

- Impellers: Impellers are the rotating components that transfer energy to the slurry, creating flow and pressure. They are designed to handle abrasive and high-solids content, making them one of the most crucial slurry pump components. Impellers are often made from high-quality alloys or rubber to provide extended service life in challenging conditions.

- Seals: Seals prevent leakage of slurry from the pump casing and protect the internal components from corrosion. Effective seals are crucial in maintaining the pump’s efficiency, and slurry pump manufacturers often offer various types, including mechanical seals and gland seals, tailored to specific applications.

- Shaft: The shaft connects the motor to the impeller, transmitting power to the impeller. The shaft is typically made from stainless steel or other corrosion-resistant materials to handle the stresses of constant rotation and exposure to abrasive slurries.

- Bearings support the shaft and enable the smooth rotation of the impeller. These components are designed to withstand heavy-duty use and are commonly made from high-grade steel or ceramics.

Types of Slurry Pumps and Their Uses

There are primarily two types of slurry pumps: centrifugal pumps and positive displacement pumps. Each type serves specific purposes based on the characteristics of the slurry being pumped.

- Centrifugal Slurry Pumps: These are the most commonly used slurry pumps. They utilize centrifugal force generated by the rotating impeller to propel the slurry through the pump. Centrifugal slurry pumps are ideal for applications where the slurry has a relatively consistent flow and moderate solids content, such as in mining, wastewater treatment, and dredging. They are highly effective at pumping large volumes of slurry over long distances.

- Positive Displacement Slurry Pumps: Unlike centrifugal pumps, positive displacement pumps work by trapping a fixed amount of slurry and forcing it through the pump. These pumps are typically used for handling slurries with a high concentration of solids or those that require high-pressure pumping. Positive displacement pumps are commonly used in applications such as thick slurry transfer in mining or slurry injection in various industrial processes.

When selecting a slurry pump, it is essential to consider the type of slurry, the required flow rate, and the pressure conditions. Working with trusted slurry pump suppliers and manufacturers ensures you get the right equipment for your specific needs, backed by high-quality slurry pump parts for optimal performance.

The Critical Role of Slurry Pump Suppliers in Material Handling

Slurry pumps play a crucial role in facilitating efficient material handling across various industries, including mining, construction, and wastewater treatment. These pumps are designed to handle mixtures of liquids and solids, which can be abrasive and challenging to transport. In mining, for example, slurry pumps are essential for transferring mineral slurry from extraction sites to processing plants. In construction, they are used for removing slurries from excavation sites. Wastewater treatment plants rely on slurry pumps to move sludge and other materials, ensuring that waste is processed and treated effectively.

Slurry pumps provide several advantages that enhance operational efficiency in material handling. Their robust design enables them to handle high-viscosity, high-abrasion, and corrosive materials, minimizing wear and tear on the equipment. By effectively moving slurry over long distances, these pumps reduce the need for additional manual labor or complex transport systems, making the material handling process faster and more cost-effective. Reliable slurry pumps ensure continuous operations, reducing downtime and improving overall productivity.

The Importance of Choosing the Right Supplier for Specific Project Requirements

Selecting the right slurry pump supplier is crucial to ensuring that the equipment meets the project’s specific needs. Different types of slurry, varying levels of solids, and unique site conditions require tailored pumping solutions. A knowledgeable slurry pump supplier understands these requirements and can recommend the most suitable slurry pump for a given application. Whether it is a centrifugal pump for consistent flow or a positive displacement pump for handling high-concentration slurry, choosing the right pump type ensures the system will perform efficiently throughout the project’s lifecycle.

Moreover, a reliable slurry pump supplier can offer valuable expertise in selecting compatible slurry pump parts that are essential for pump longevity and reliability. High-quality components, including seals, bearings, and impellers, ensure optimal performance and minimize maintenance costs. Suppliers with a strong reputation in the industry often provide comprehensive support, including custom solutions, product testing, and expert advice, ensuring that clients get the right pump configuration for their specific project.

How Slurry Pump Suppliers Impact Operational Efficiency and Project Success

Slurry pump suppliers have a direct impact on the operational efficiency and success of any project that involves the movement of abrasive materials. A reputable supplier provides high-quality equipment that operates at peak efficiency, reducing the risk of breakdowns and unscheduled downtime. By offering pumps that are specifically designed for the demands of the material being handled, suppliers help maintain a steady flow of operations, allowing projects to stay on track and meet deadlines.

In addition, suppliers who offer comprehensive after-sales support, including maintenance services and readily available spare parts, ensure that slurry pumps continue to perform optimally throughout their service life. This ongoing support is essential in preventing equipment failure, minimizing repair costs, and enhancing overall project success. By partnering with trusted slurry pump manufacturers and suppliers, companies can improve their material handling operations and achieve better results with less effort.

Selecting the Right Slurry Pump Manufacturer

The performance of a slurry pump depends on the quality and condition of its parts. Slurry pumps are designed to handle abrasive materials, high solids content, and varying flow rates, and each component must work together to ensure optimal performance. Understanding the role of key slurry pump parts and how they impact performance is essential for maintaining efficiency, reducing downtime, and minimizing maintenance costs. Below is a breakdown of the various parts of a slurry pump and their contributions to its overall function.

Impellers

Impellers are one of the most critical components of a slurry pump. They are responsible for generating the flow of slurry by transferring kinetic energy to the material. Impellers are designed to handle the abrasive nature of slurry and must be built from durable materials, such as high-chrome alloys or rubber linings. The design and material choice of the impeller directly affect the pump’s ability to handle high volumes and resist wear over time. High-quality impellers improve the pump’s efficiency, reducing the need for frequent maintenance or replacements. Reliable slurry pump suppliers ensure that impellers are designed to meet the specific flow and pressure requirements of each application, maximizing performance.

Bearings

Bearings support the shaft, allowing for the smooth rotation of the impeller. They are essential for maintaining proper alignment and minimizing friction during pump operation. If bearings are worn or damaged, it can lead to excessive heat generation, vibration, and potential pump failure. High-quality bearings help extend the lifespan of the slurry pump and reduce the risk of costly downtime. Slurry pump manufacturers focus on using corrosion-resistant and durable materials for bearings, ensuring that they can withstand the abrasive environments in which slurry pumps operate.

Shaft Sleeves

The shaft sleeve protects the pump shaft from wear caused by the abrasive nature of the slurry. As the slurry flows through the pump, the shaft comes into contact with particles that can erode the surface, leading to pump inefficiency and failure. Shaft sleeves are made from wear-resistant materials that can absorb the impact of solids in the slurry, preventing damage to the pump shaft. When shaft sleeves are regularly replaced, the pump can maintain optimal performance and avoid costly repairs. Reputable slurry pump suppliers offer high-quality shaft sleeves designed to match the specific requirements of the pump system.

Seals and Gaskets

Seals and gaskets are responsible for preventing leakage of slurry from the pump casing and protecting internal components from corrosion. These parts also prevent contaminants from entering the pump, which can affect its performance and the performance of its components. Effective seals and gaskets are essential for maintaining pressure within the system and ensuring that the slurry is contained during transport. Over time, seals and gaskets can wear out, resulting in leakage or a decrease in pump efficiency. Suppliers of slurry pumps offer a variety of sealing solutions designed to withstand harsh slurry conditions and ensure leak-free operation. Selecting the correct slurry pump parts for sealing can significantly reduce maintenance costs and extend the pump’s lifespan.

The Role of Slurry Pump Parts in Preventing Downtime and Reducing Maintenance Costs

Each slurry pump part plays a vital role in ensuring the pump operates efficiently. When these parts are of high quality and are regularly maintained or replaced, the risk of downtime is minimized. Downtime is costly, especially in industries such as mining and construction, where continuous operations are crucial. High-quality slurry pump parts, when properly maintained, also reduce the need for frequent repairs, which in turn reduces overall maintenance costs. By selecting slurry pumps with durable, high-performance parts, companies can achieve significant long-term cost savings while also enhancing the reliability of their operations.

How Suppliers Ensure That All Parts Meet Quality Standards and Are Compatible with the Main Pump System

Reputable slurry pump suppliers and manufacturers ensure that all pump parts meet industry quality standards and are compatible with the main pump system. These suppliers conduct rigorous testing on all components to verify their durability, performance, and ability to operate under extreme conditions. They also provide detailed specifications and guidelines for selecting compatible slurry pump parts, ensuring the pump operates efficiently and safely. By sourcing parts from trusted suppliers, customers can ensure that all components work together seamlessly, improving the pump’s performance and reducing the likelihood of failures due to incompatible parts.

Selecting a slurry pump supplier that offers high-quality parts and reliable after-sales support is crucial for maximizing the longevity and efficiency of slurry pumps in material handling applications.

Maintenance and Support Provided by Slurry Pump Suppliers

After-sales service and maintenance support are essential aspects of ensuring the long-term reliability and performance of slurry pumps. Slurry pumps are designed for heavy-duty, high-abrasion environments, and without proper maintenance, their efficiency can degrade over time. Reputable slurry pump suppliers not only provide high-quality pumps but also offer comprehensive support to ensure that their equipment continues to perform optimally throughout its lifespan.

Importance of After-Sales Service and Maintenance Support

After-sales service is crucial in minimizing downtime and ensuring that slurry pumps operate at peak performance. A reliable supplier will provide ongoing support after the initial sale, including routine maintenance checks, troubleshooting, and repairs. Maintenance services help detect potential issues early, allowing for timely interventions that prevent larger, more costly breakdowns. With the right support, slurry pumps can maintain high efficiency and avoid unexpected failures, which is particularly important in industries such as mining, wastewater treatment, and construction. Regular service visits, combined with technical assistance, contribute to better pump longevity and reduced operational disruptions.

How Slurry Pump Suppliers Offer Parts, Technical Support, and Advice to Maximize Pump Efficiency

Slurry pump suppliers ensure that spare parts, technical support, and expert advice are readily available to customers. By offering a wide range of slurry pump parts, such as impellers, bearings, seals, and gaskets, suppliers enable clients to replace worn components, thereby maintaining continuous pump operation quickly. This minimizes downtime and extends the overall life of the pump system.

In addition to providing parts, slurry pump suppliers often offer technical support to help customers troubleshoot and resolve any issues that may arise. Whether it’s guidance on system setup, identifying problems, or optimizing performance, suppliers can provide valuable expertise that ensures the pump operates efficiently. Some suppliers also offer predictive maintenance services, using advanced monitoring tools to forecast potential failures and proactively address issues before they affect operations.

The Role of Suppliers in Training and Educating Clients on the Maintenance of Slurry Pumps

Training and education are key components of effective slurry pump maintenance. Reputable slurry pump manufacturers and suppliers recognize the importance of equipping clients with the knowledge and skills necessary to perform routine maintenance and handle minor repairs themselves. This helps to reduce dependency on external support and enables operators to address issues promptly before they escalate.

Suppliers often provide training programs that cover topics such as proper installation, routine inspection, part replacement, and troubleshooting techniques. These training sessions are typically tailored to the specific needs of the client and their equipment. By empowering clients with this knowledge, suppliers contribute to improved pump performance and reduced maintenance costs.

By offering comprehensive maintenance and support services, slurry pump suppliers help clients maximize the efficiency and lifespan of their equipment, ensuring reliable operations and minimal downtime across various industries.

Final Thoughts on Choosing the Right Slurry Pump Supplier and Maximizing Performance

Slurry pumps are essential tools in industries that require efficient material handling, particularly in challenging environments where abrasive and high-viscosity slurries are involved. Choosing the right slurry pump supplier and ensuring the quality of components, such as impellers, bearings, and seals, is crucial for maintaining high performance, minimizing downtime, and reducing operational costs. A reliable slurry pump supplier not only provides high-quality products but also offers ongoing maintenance support, expert advice, and training to maximize pump efficiency and performance.

At Virginia Dredging, we are committed to providing top-tier slurry pumps, components, and after-sales services tailored to your specific needs. Our team of experts ensures you receive the best solutions for your slurry handling requirements, backed by comprehensive technical support and maintenance services. Ready to enhance the efficiency of your dredging operations? Contact us today at Virginia Dredging to learn more about our slurry pump solutions and how we can help keep your equipment running optimally.