Pumping high-viscosity liquids presents unique challenges that standard pumping equipment cannot always overcome. From adhesives and sludge to food pastes and heavy oils, these fluids demand specialized designs that can handle increased resistance, higher energy loads, and potential product sensitivity. Selecting the right pump for high viscosity applications is essential to ensure consistent performance, reduced maintenance, and long-term operational efficiency.

The Science of Resistance: How Viscosity Affects Fluid Flow

When working with viscous materials, the fundamental challenge lies in overcoming resistance to flow. Viscosity is the measure of a fluid’s internal friction, and as viscosity increases, the effort required to move the fluid through pipelines, fittings, or pump components rises significantly. This resistance directly translates into higher energy demand, reduced flow efficiency, and greater stress on pumping equipment.

For standard low-viscosity liquids such as water or light oils, centrifugal pumps perform adequately because the fluid flows easily under pressure. However, as liquids become thicker—such as adhesives, sludge, or heavy lubricants—the same pump struggles to maintain performance. The dense nature of these fluids creates additional drag, which increases pressure drops across the system and results in lower discharge rates.

This is where selecting the right pump for high viscosity becomes critical. A standard design may fail due to overheating, cavitation, or wear, while a properly engineered high viscosity pump is built to manage heavy, slow-moving fluids without compromising efficiency. Depending on the application, different high viscosity pump types—such as gear pumps, progressive cavity pumps, or twin-screw pumps—offer unique advantages in handling resistance, ensuring consistent flow, and reducing operational strain.

Hidden Hurdles: Core Challenges of Pumping Viscous Liquids

Pumping viscous liquids introduces a range of technical challenges that go beyond standard fluid handling. Choosing the right pump for high viscosity is essential to address these hurdles and maintain reliable system performance.

Flow Restrictions and Reduced Transfer Speed

High-viscosity fluids resist movement, which results in slower flow rates and reduced transfer efficiency. Standard centrifugal pumps struggle to move these liquids effectively, making specialized high viscosity pump types—such as progressive cavity or gear pumps—more suitable.

Increased Power Requirements and Motor Strain

As viscosity increases, the pump requires more torque to overcome resistance. This higher demand can place additional strain on motors and drive systems, leading to overheating or reduced equipment life if the system is not designed for thick fluids.

Risks of Shear Damage to Sensitive Products

Many viscous materials, such as food pastes, polymers, or cosmetics, are shear-sensitive. A standard pump can cause product degradation or structural changes under high shear forces. A properly designed high viscosity pump minimizes shear impact while ensuring smooth transfer.

Cavitation, Clogging, and Mechanical Stress

Thick liquids increase the likelihood of cavitation when suction conditions are not optimized. In addition, particles suspended in viscous fluids can clog narrow passages, creating pressure surges and mechanical stress on pump components.

Accelerated Wear in Pump Internals

Handling dense, abrasive, or sticky materials accelerates wear on internal components such as seals, bearings, and rotors. Using the correct high viscosity pump types with wear-resistant materials and appropriate sealing systems can reduce downtime and maintenance costs.

Exploring the Arsenal: High Viscosity Pump Types

Selecting the right pump for high viscosity applications depends heavily on the nature of the fluid, operating conditions, and industry requirements. Different high viscosity pump types offer unique strengths, making it important to match the pump design to the process demands. Below are the most widely used options and where they perform best.

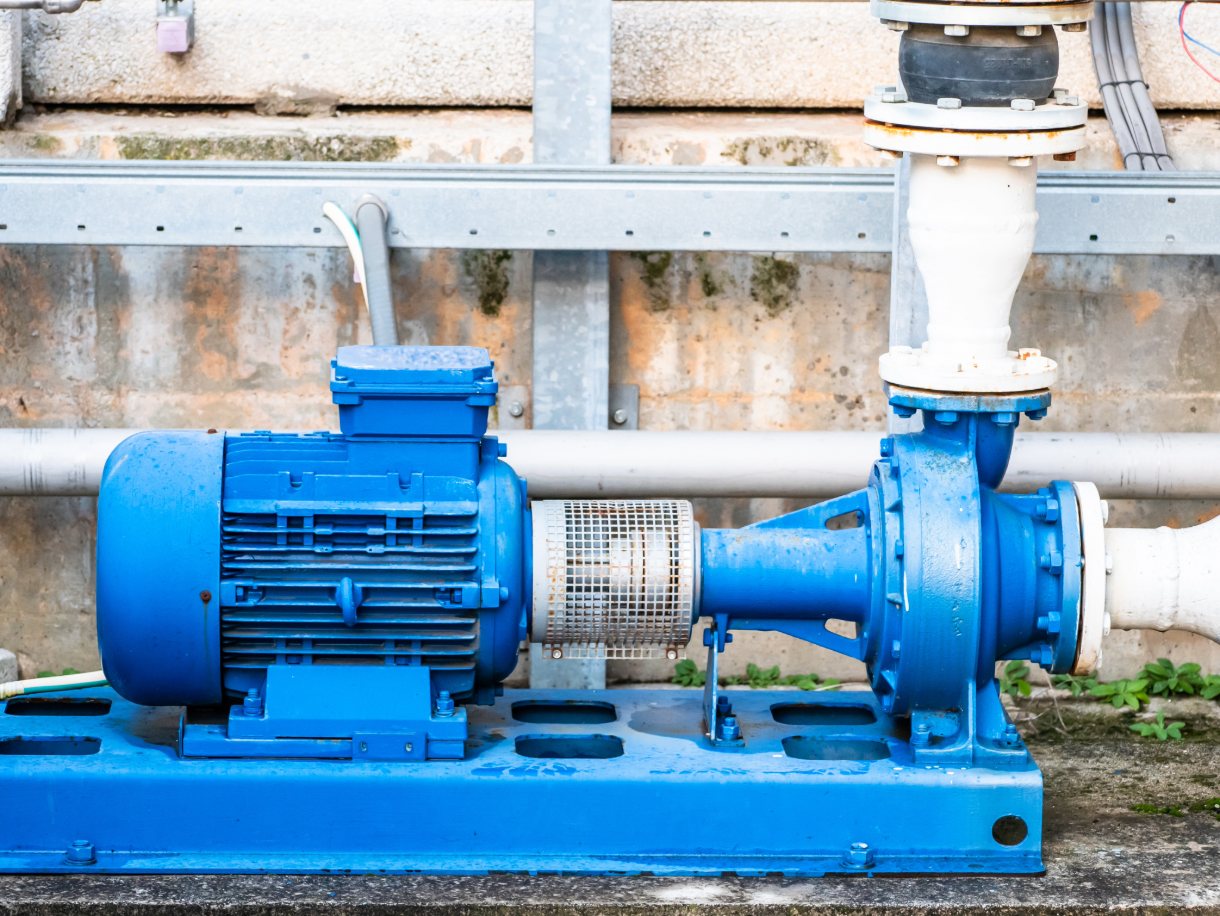

Gear and Lobe Pumps – Reliable Performance for Industrial Fluids

Gear and lobe pumps are positive-displacement designs that provide steady, pulseless flow. They are well-suited for pumping oils, resins, and other viscous industrial fluids. Their robust construction handles moderate to high viscosities, though they are not ideal for shear-sensitive products due to the pressure exerted during pumping.

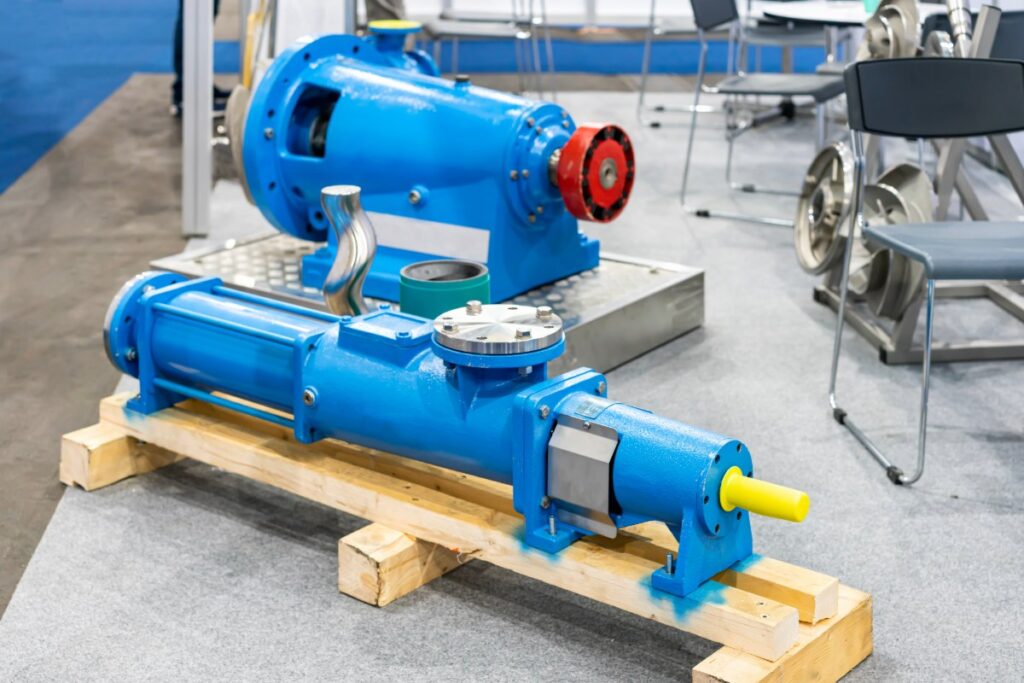

Progressive Cavity Pumps – Gentle Flow for Slurries and Pastes

Progressive cavity pumps use a helical rotor and stator design to move thick fluids smoothly and with minimal shear. This makes them particularly effective for slurries, adhesives, wastewater sludge, and food pastes. They are often chosen as a high viscosity pump when consistent flow and low-shear handling are critical.

Diaphragm Pumps – Versatility for Abrasive and Shear-Sensitive Materials

Air-operated or mechanical diaphragm pumps are valued for their ability to handle abrasive, viscous, and shear-sensitive liquids without damaging the product. They are commonly used in chemical processing, paints, and coatings. Their simple design allows them to transfer fluids that may contain solids or contaminants, reducing clogging risks.

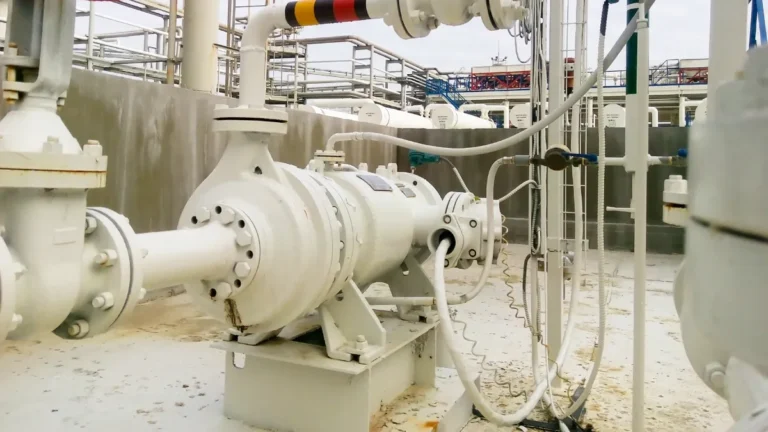

Twin-Screw Pumps – Hygienic Transfer for Food and Pharmaceuticals

Twin-screw pumps excel in hygienic industries where cleanability and product integrity are vital. They can handle high-viscosity materials such as creams, syrups, and gels, while also managing low-viscosity liquids in the same system. Their ability to run dry for short periods and maintain gentle, continuous flow makes them one of the most versatile high viscosity pump types.

Comparative Insights by Industry

- Industrial manufacturing: Gear and lobe pumps are preferred for oils, lubricants, and resins.

- Wastewater and environmental: Progressive cavity pumps provide reliable sludge handling.

- Chemicals and coatings: Diaphragm pumps are effective for abrasive and shear-sensitive compounds.

- Food, beverage, and pharma: Twin-screw pumps deliver hygienic, low-shear transfer for sensitive materials.

By aligning the pump choice with fluid properties and process requirements, businesses can ensure reliable performance and extended equipment life in high-viscosity applications.

Engineering Smarts: Design Innovations That Make It Work

Modern engineering has made it possible for pumps designed for high-viscosity applications to handle thicker, more complex fluids with efficiency and reliability. Several design innovations ensure that these systems overcome the challenges of resistance, wear, and flow restrictions.

Oversized Suction and Discharge Ports

High-viscosity fluids require wider passages to move effectively. Oversized inlet and outlet ports reduce friction losses and minimize the risk of clogging. This design feature allows a high viscosity pump to maintain stable flow rates even with dense or sticky liquids.

Variable-Speed Drives for Adaptability

Viscosity can change depending on temperature and process conditions. Equipping pumps with variable-frequency drives (VFDs) enables precise speed control, ensuring optimal performance across a wide viscosity range. Many high-viscosity pump types use this technology to reduce energy consumption and extend equipment life.

Material Choices That Resist Abrasion and Corrosion

Thick fluids often contain abrasive particles or chemically aggressive compounds. Pumps constructed with hardened alloys, stainless steel, or specialized coatings are more durable and resistant to wear. Selecting the right materials for a pump for high viscosity reduces downtime and extends service intervals.

Heating Jackets to Lower Viscosity During Pumping

In industries where liquids can be heated without damage, jacketed pumps provide controlled heating to reduce viscosity. Lowering fluid thickness makes it easier for the pump to transfer the material, improving efficiency and lowering energy demand. This feature is especially common in certain high-viscosity pump types used in asphalt, chocolate, or resin processing.

Modern Sealing Solutions for Leak Prevention

High-viscosity fluids exert greater pressure on seals, which increases the risk of leaks. Mechanical seals and advanced sealing systems are designed to withstand these stresses while keeping maintenance to a minimum. The right sealing technology ensures that a high viscosity pump operates reliably under demanding conditions.

Setting Up for Success: Best Practices in Installation & Operation

Even the most advanced pump for high viscosity requires proper installation and operation to perform effectively. Following best practices helps minimize energy losses, reduce wear, and extend equipment life in demanding applications.

Positioning Pumps for Minimal Suction Lift

High-viscosity fluids are more difficult to draw into the pump, making suction conditions critical. Positioning the high viscosity pump as close as possible to the fluid source reduces suction lift and prevents cavitation. A flooded suction setup is often preferred for consistent priming and smoother operation.

Pipework Layouts That Prevent Flow Restrictions

Piping design plays a major role in handling thick liquids. Short, straight suction lines with gradual bends help minimize resistance, while oversized pipes reduce friction losses. Properly designed layouts ensure that different high-viscosity pump types maintain steady flow without unnecessary strain.

Routine Inspection, Lubrication, and Viscosity Monitoring

Viscous materials place extra stress on bearings, seals, and other moving parts. Regular lubrication and inspection are essential to prevent premature wear. In addition, monitoring fluid viscosity ensures that the pump for high viscosity operates within its design limits, preventing overload or inefficiency.

Extending Service Life Through Predictive Maintenance

Modern facilities often use predictive maintenance strategies, such as vibration analysis, temperature monitoring, and flow tracking, to detect early signs of wear. These practices reduce downtime, optimize performance, and extend the lifespan of high-viscosity pumps used in continuous or heavy-duty operations.

Efficiency at Stake: Balancing Energy and Costs

Energy efficiency is one of the most important considerations when selecting a pump for high viscosity applications. Because thick fluids require greater force to move, the wrong pump choice can significantly increase operating expenses over time.

How Pump Selection Impacts Long-Term Operating Expenses

Choosing the correct high viscosity pump directly affects maintenance frequency, energy demand, and downtime. A poorly matched pump may consume excessive power, wear out components quickly, and require frequent repairs. In contrast, selecting the right design ensures smoother flow and reduced lifecycle costs.

Energy Trade-Offs in Oversized vs. Properly Sized Pumps

Oversizing is a common mistake when handling viscous liquids. While an oversized pump may initially appear more powerful, it often wastes energy and creates unnecessary strain on drive systems. On the other hand, an undersized unit will struggle to maintain flow, leading to overheating and premature failure. Matching pump capacity to the actual process requirements allows different high viscosity pump types to operate at peak efficiency without energy loss.

The Economic Benefits of Choosing the Right Pump for High Viscosity

Investing in a pump specifically engineered for viscous fluids reduces the total cost of ownership. Features such as variable-speed drives, oversized ports, and wear-resistant materials not only improve efficiency but also lower energy consumption. By carefully selecting the best high viscosity pump types for the application, facilities can achieve reliable performance, minimize downtime, and maintain cost-effective operations.

Tomorrow’s Tech: Future of High Viscosity Pumping

Advancements in engineering and digital technologies are shaping the next generation of solutions for handling viscous fluids. Future-ready designs focus on improving efficiency, reducing downtime, and supporting sustainable operations in industries that depend on a pump for high viscosity applications.

Smart Monitoring Systems That Auto-Adjust to Viscosity Changes

Viscosity can fluctuate due to temperature shifts, process variations, or material inconsistencies. Smart control systems are being developed to monitor these changes in real time and automatically adjust pump speed and pressure. This ensures that each high viscosity pump operates at optimal performance, reducing energy waste and mechanical stress.

Integration of IoT for Predictive Performance

The integration of Internet of Things (IoT) technology allows pumps to be equipped with sensors that continuously track parameters such as flow, pressure, vibration, and temperature. Data collected from connected high viscosity pump types enables predictive maintenance, helping operators detect issues before failures occur. This reduces downtime and extends equipment life.

Emerging Materials and Eco-Friendly Designs

New material technologies are improving pump durability and efficiency. Advanced composites and wear-resistant alloys provide better protection against abrasion and corrosion, while lightweight components reduce energy consumption. In addition, eco-friendly designs are becoming more common, with high viscosity pump types engineered to reduce environmental impact through lower energy use and improved recyclability of components.

Choosing the Right Path for High Viscosity Applications

Handling viscous fluids effectively requires a balance of smart engineering, proper pump selection, and best operational practices. By understanding the limitations of standard equipment and choosing the right high viscosity pump types, industries can achieve reliable performance while minimizing costs and downtime. For tailored solutions that address your specific pumping challenges, we at Virginia Dredging are ready to provide the expertise and equipment you need to keep your operations running efficiently.